Diamond core drills have become an essential tool across construction, manufacturing, stone processing, electronics, and advanced engineering applications. Known for their precision, durability, and ability to cut through the hardest materials, these tools outperform conventional drilling methods when accuracy and surface integrity matter most.

As industries evolve and demand cleaner cuts, tighter tolerances, and higher productivity, diamond drilling technology continues to set the benchmark. This guide explores how diamond core drills work, their applications, advantages, material compatibility, and how to choose the right diamond core drill bits for your specific needs.

What Are Diamond Core Drills?

Diamond core drills are specialized cutting tools designed to drill precise cylindrical holes in hard, brittle, or dense materials. Unlike standard drills that rely on sharp edges, diamond drills use industrial-grade diamond particles bonded to the cutting surface. These diamonds grind through materials rather than tearing them, resulting in smooth, accurate holes with minimal damage.

Diamond core drilling is widely used where traditional drilling would cause cracking, chipping, or excessive wear. The technology supports both wet and dry drilling methods depending on material type and application.

How Diamond Core Drilling Works

The cutting mechanism of diamond core drills relies on abrasion rather than impact. The diamond particles embedded in the drill bit rotate at controlled speeds, gradually removing material layer by layer. This process reduces stress on the workpiece and produces consistent results even on extremely hard surfaces.

Key components involved in diamond drilling include:

Diamond-impregnated cutting segments

Metal or resin bond matrix

Hollow core design for material removal

Cooling system (water or air, depending on use)

The hollow structure allows debris to exit efficiently while maintaining drilling accuracy.

Key Advantages of Diamond Core Drills

Superior Precision and Clean Cuts

Diamond core drill bits create smooth, round holes with tight tolerances. This makes them ideal for applications requiring exact alignment or finishing quality.

Extended Tool Life

Industrial diamonds are among the hardest materials known. When properly matched to the application, diamond drills offer significantly longer service life compared to carbide or steel alternatives.

Reduced Material Damage

Because diamond drilling is a low-vibration process, it minimizes cracking, spalling, and chipping, especially in brittle materials like glass, ceramics, and stone.

Versatility Across Materials

Diamond core drills can be used on concrete, reinforced concrete, granite, marble, quartz, sapphire, ceramics, composites, silicon, and advanced engineered materials.

Common Applications of Diamond Core Drills

Diamond core drills are used across a wide range of industries, including:

Construction and Infrastructure

Concrete coring for plumbing and electrical systems

HVAC and pipe installation

Structural anchoring and retrofitting

Stone and Tile Processing

Drilling granite, marble, quartz countertops

Tile installation and decorative stonework

Electronics and Semiconductor Manufacturing

Drilling silicon wafers

Precision holes in ceramic substrates

Microelectronics component fabrication

Aerospace and Advanced Engineering

Composite material drilling

Precision cooling channels

Lightweight structural components

Glass and Optical Industries

Clean drilling in glass panels

Optical component manufacturing

Types of Diamond Core Drill Bits

Wet Diamond Core Drill Bits

Wet drilling uses water to cool the bit and flush away debris. This method increases bit lifespan, improves cut quality, and is preferred for hard or dense materials such as reinforced concrete and stone.

Dry Diamond Core Drill Bits

Dry drilling does not require water and is often used in indoor or portable applications. These bits typically feature special bonding and ventilation slots for heat dissipation.

Resin Bond Diamond Drills

Ideal for delicate materials requiring ultra-smooth finishes. Resin bonds offer excellent surface quality but may wear faster on very hard materials.

Metal Bond Diamond Core Drills

Designed for aggressive cutting and durability. Metal bonds are commonly used in construction, stone, and industrial applications.

Choosing the Right Diamond Core Drills

Selecting the correct diamond core drill bits depends on several critical factors:

Material Type

Hardness, abrasiveness, and brittleness all affect bond selection and diamond concentration.

Hole Diameter and Depth

Different applications require varying core sizes and drilling depths. Thicker materials may require segmented or longer drill bits.

Machine Compatibility

Ensure the drill bit matches the spindle, RPM range, and power of your drilling equipment.

Cooling Method

Determine whether wet or dry drilling is appropriate based on job conditions and material sensitivity.

Diamond Drills vs Traditional Drilling Tools

Diamond drills outperform traditional tools in situations where precision, durability, and surface quality are critical. While conventional drills may be suitable for wood or soft metals, they struggle with advanced materials and often cause microfractures.

Diamond core drilling offers:

Higher accuracy

Less rework

Reduced downtime

Lower long-term tooling costs

Maintenance and Best Practices

To maximize performance and lifespan:

Use proper RPM and feed rates

Match the drill bit to the material

Ensure adequate cooling when wet drilling

Avoid excessive pressure

Dress the bit periodically if cutting efficiency drops

Proper handling and storage also prevent unnecessary damage to diamond segments.

Sustainability and Efficiency Benefits

Diamond core drills support sustainable manufacturing by reducing material waste, energy consumption, and tool replacement frequency. Cleaner cuts mean fewer rejects, while longer tool life reduces overall resource usage.

Industry Innovation and Customization

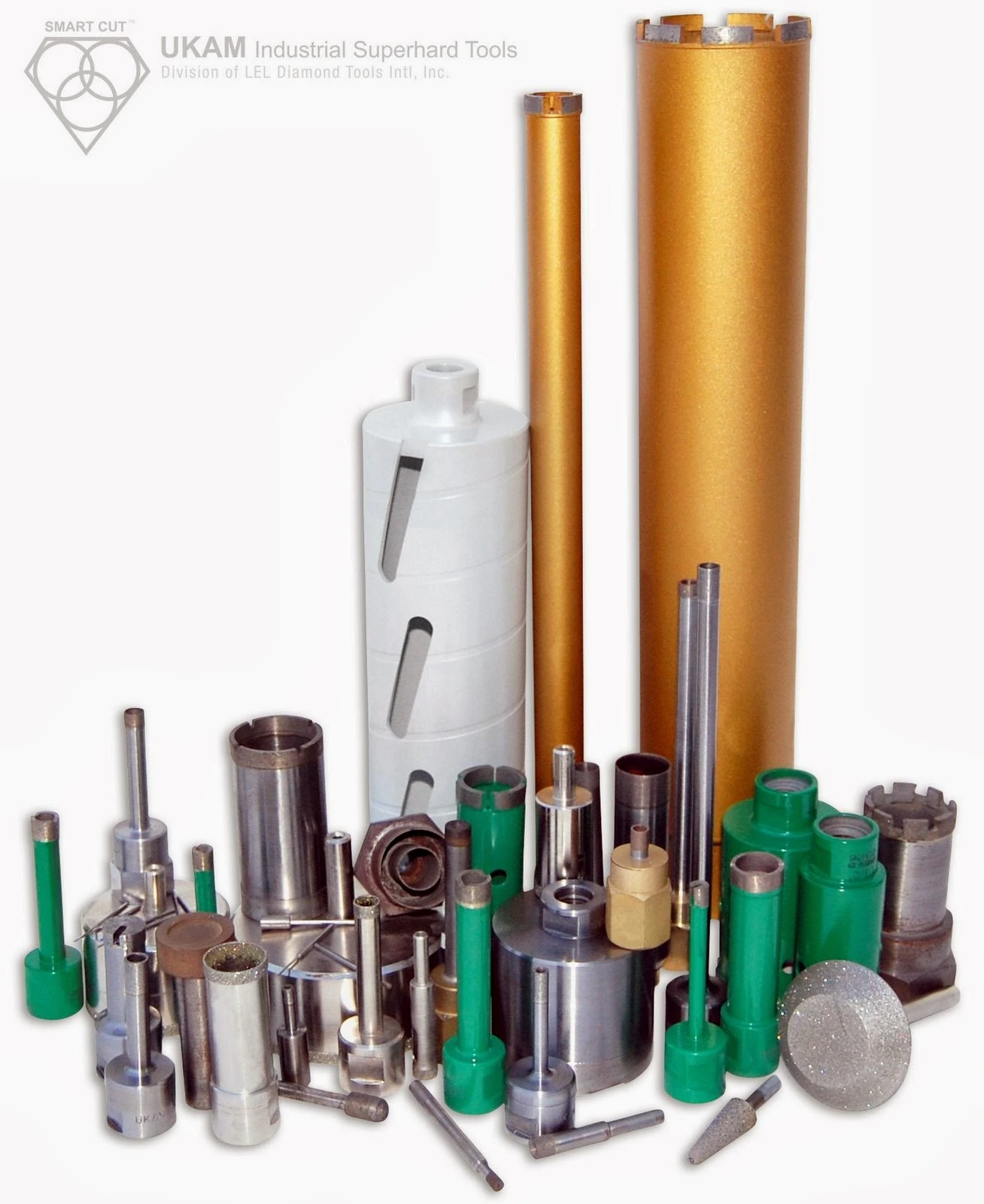

Manufacturers continue to innovate in diamond drilling technology, offering custom-designed solutions tailored to specific materials and applications. Companies like UKAM develop precision-engineered diamond core drills that meet demanding industrial requirements across global markets.

Frequently Asked Questions

What materials can diamond core drills cut?

Diamond core drills can cut concrete, reinforced concrete, granite, marble, ceramics, glass, silicon, composites, quartz, sapphire, and engineered materials.

Are diamond core drill bits reusable?

Yes. When used correctly, diamond core drill bits are highly durable and can be reused multiple times until the diamond segments wear out.

What is the difference between diamond drills and diamond core drills?

Diamond drills typically refer to solid or small-diameter tools, while diamond core drills are hollow and designed for larger, deeper holes.

Do diamond core drills require water?

Not always. Wet drilling is recommended for hard materials, but dry diamond core drill bits are available for applications where water is not feasible.

How long do diamond core drill bits last?

Tool life depends on material type, operating conditions, and maintenance. Proper usage can significantly extend lifespan.

Key Takeaways

Diamond core drills represent the gold standard in precision drilling for hard and advanced materials. Their unmatched accuracy, durability, and versatility make them indispensable across industries ranging from construction to electronics and aerospace. By selecting the right diamond core drill bits and following best practices, professionals can achieve superior results while optimizing efficiency and cost.

As technology continues to advance, diamond drilling solutions will remain at the forefront of high-performance material processing.