When it comes to achieving precision cutting in advanced materials, few tools match the efficiency and accuracy of diamond wafering blades. Designed specifically for thin sectioning and delicate cutting tasks, these blades are the preferred choice across industries such as electronics, semiconductor, metallurgy, geology, optics, and advanced ceramics. Their unique design allows users to cut hard and brittle substrates while minimizing damage, material loss, and chipping.

What are Diamond Wafering Blades?

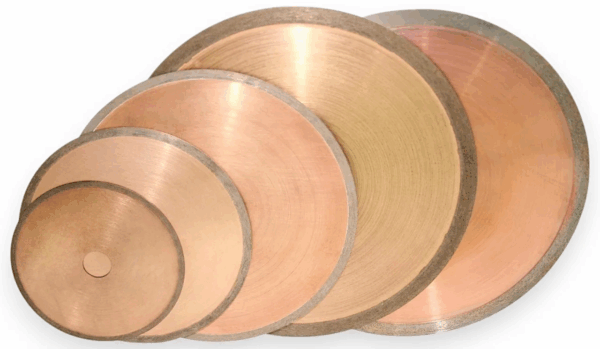

Diamond wafering blades are ultra-thin circular blades embedded with diamond particles along the rim. Diamonds, being the hardest known material, provide unmatched cutting capability for extremely hard and brittle substances. These blades are commonly used in low-speed saws and precision cutting machines to section materials such as glass, ceramics, quartz, composites, semiconductors, and advanced metals.

The key advantage lies in their ability to create thin sections with low kerf loss, meaning less material waste during the cutting process. This is particularly critical in industries where material samples are valuable and where structural integrity must be preserved.

Applications of Diamond Wafering Blades

Semiconductor Industry In the fabrication of microchips and electronic components, diamond wafering blades ensure precise sectioning of silicon wafers and other semiconductor materials. Accuracy is vital here, as even the slightest error can lead to performance issues in final devices.

Metallography For metallographic analysis, these blades are used to cut thin slices of metal samples without altering their microstructure. This allows researchers and engineers to study grain boundaries, phases, and defects under microscopes without introducing artifacts.

Geology and Mineralogy Geologists use wafering blades to section rocks, gemstones, and mineral samples. The precision cutting ability ensures clean surfaces that can be examined under microscopes for research or classification.

Ceramics and Glass Cutting Advanced ceramics and glass are notoriously brittle. Using diamond wafering blades helps reduce cracking, edge chipping, and thermal damage during cutting, making them essential for laboratories and manufacturing environments.

Optics and Photonics In optics, thin and uniform samples are crucial for producing lenses, crystals, and other optical components. Diamond wafering blades provide accuracy and consistency, enabling the production of high-performance optical parts.

Benefits of Using Diamond Wafering Blades

Precision and Accuracy – Achieve ultra-thin cuts with tight tolerances.

Low Kerf Loss – Minimize material waste, which is especially important when working with costly or limited materials.

Versatility – Suitable for a wide range of hard and brittle substrates, including ceramics, composites, quartz, and sapphire.

Surface Integrity – Reduce edge damage and preserve the natural properties of the material.

Consistency – Deliver uniform results for both research and production applications.

Choosing the Right Diamond Wafering Blade

Selecting the right blade depends on several factors, including:

Material Hardness – Softer materials may require a different grit size compared to ultra-hard substrates.

Blade Thickness – Thinner blades are preferred for low kerf loss, while thicker blades may be necessary for durability.

Bond Type – The bond material holding the diamonds in place affects cutting speed and blade life.

Cutting Speed and Equipment – Ensure compatibility with your low-speed saw or precision cutting machine.

Final Thoughts

Diamond wafering blades are indispensable tools for industries that demand high precision and reliability. Whether it’s slicing delicate semiconductors, preparing metallographic samples, or cutting brittle ceramics and glass, these blades consistently deliver accuracy, efficiency, and low material loss. By choosing the right blade for your application, you can optimize performance, improve results, and extend tool life—making them a cornerstone of modern precision cutting technology.