Diamond core drills are essential tools in industries where accuracy, clean cuts, and material integrity matter most. From construction and infrastructure projects to stone fabrication, electronics, and advanced manufacturing, these tools enable professionals to drill precise holes in some of the hardest materials on earth. When chosen correctly, diamond core drills improve productivity, reduce downtime, and deliver consistent results across demanding applications.This in-depth guide explores how diamond core drills work, where they are used, how to choose the right type, and why quality manufacturing makes a measurable difference in performance.

What Are Diamond Core Drills?

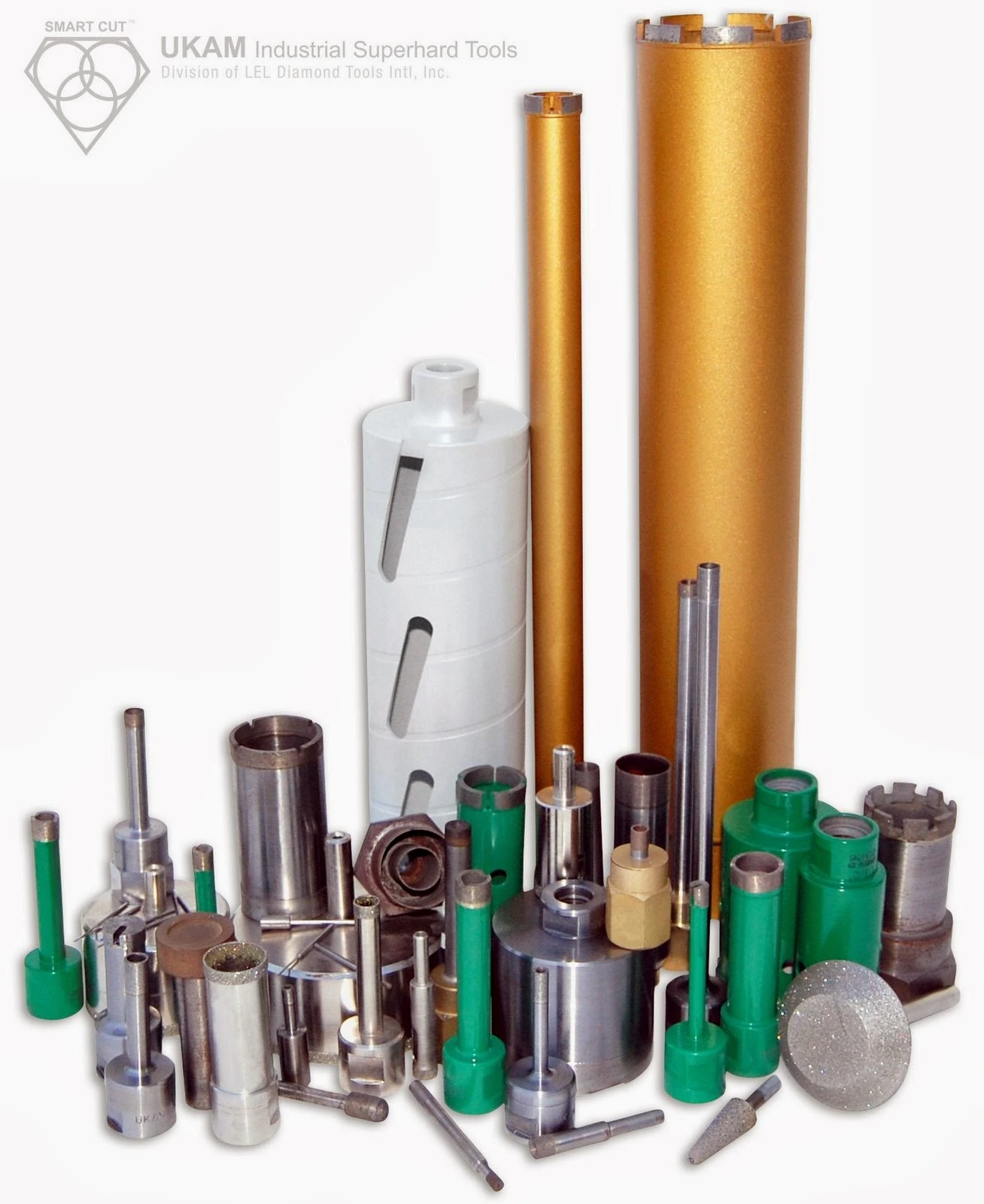

Diamond core drills are specialized cutting tools designed to drill cylindrical holes in hard and brittle materials such as concrete, reinforced concrete, granite, marble, ceramics, glass, composites, and engineered stone. Instead of using traditional cutting edges, these drills rely on industrial-grade diamonds bonded to the cutting segment to grind through material with precision.Unlike conventional drill bits, diamond core drills remove a solid “core” from the material. This method reduces vibration, minimizes cracking, and ensures smooth, accurate holes—making them ideal for high-precision and structural applications.

How Diamond Core Drills Work

The cutting action of diamond core drills is based on abrasion rather than impact. As the drill rotates, exposed diamond particles grind away the material at a controlled rate. Bond systems are engineered to wear gradually, constantly exposing fresh diamonds for consistent cutting performance.Key components include:

- Diamond segments or rims that perform the cutting

- Metal or resin bonds that control diamond exposure

- Steel core body that maintains stability and alignment

This design allows diamond core drills to handle extreme hardness while maintaining dimensional accuracy.

Applications Across Industries

Diamond core drills are widely used across multiple sectors due to their versatility and reliability:

Construction and Infrastructure

They are commonly used for drilling holes for plumbing, electrical conduits, HVAC systems, anchor bolts, and structural testing in concrete and masonry.

Stone and Tile Fabrication

Granite, marble, quartz, and porcelain require clean, chip-free holes. Diamond core drills ensure smooth finishes, especially in visible or decorative surfaces.

Electronics and Advanced Manufacturing

Precision drilling in ceramics, glass substrates, and composites is critical in electronics and semiconductor manufacturing, where tolerances are extremely tight.

Automotive and Aerospace

Composite materials and high-strength alloys used in these industries demand tools that can drill accurately without causing delamination or microcracks.

Types of Diamond Core Drills

Choosing the right diamond core drill depends on the application, material, and operating conditions.

Wet Diamond Core Drills

Designed to be used with water or coolant, wet drills reduce heat, extend tool life, and improve cutting speed. They are ideal for concrete, stone, and heavy-duty industrial applications.

Dry Diamond Core Drills

Dry drilling systems are used where water is not practical. Advanced bond technology allows efficient cutting with dust extraction systems, commonly used in renovation and indoor construction work.

Segmented vs. Continuous Rim

- Segmented drills offer faster cutting and better cooling for tough materials

- Continuous rim drills provide smoother finishes, especially for glass, tile, and ceramics

The right configuration ensures both performance and surface quality.

Why Quality Matters in Diamond Core Drills

Not all diamond core drills are created equal. Tool performance is directly influenced by diamond quality, bond formulation, and manufacturing precision. High-quality drills deliver:

- Faster drilling speeds

- Longer tool life

- Reduced material damage

- Lower overall operating costs

Professionals rely on manufacturers with deep expertise in superabrasive technology. Companies like UKAM Industrial Superhard Tools focus on precision engineering and application-specific solutions, ensuring consistent results even in the most demanding environments.

Selecting the Right Diamond Core Drill

To maximize efficiency and tool life, consider the following factors:

Material Type

Different materials require different bond hardness and diamond concentration. Hard materials need softer bonds, while softer materials require harder bonds.

Hole Diameter and Depth

Larger diameters and deeper holes require robust core bodies and optimized segment design to maintain stability.

Machine Compatibility

Ensure the drill matches the spindle type, RPM range, and power output of your drilling equipment.

Cooling Method

Decide between wet or dry drilling based on jobsite conditions and material sensitivity.Using the correct diamond core drill bits for your application not only improves results but also enhances operator safety and project timelines.

Performance Benefits of Diamond Core Drills

When properly selected and used, diamond core drills offer measurable advantages:

- High precision with minimal deviation

- Clean, smooth holes with reduced finishing work

- Lower vibration and noise compared to impact drilling

- Improved efficiency on hard and brittle materials

These benefits make diamond core drills indispensable in both heavy-duty industrial environments and precision manufacturing settings.

Maintenance and Best Practices

To get the most out of diamond core drills:

- Use the recommended RPM and feed rate

- Ensure adequate cooling for wet applications

- Avoid excessive pressure that can glaze the diamonds

- Dress the tool if cutting speed decreases

Routine inspection and proper handling significantly extend tool life and maintain consistent cutting performance. Choosing high-quality diamond core drill bits also reduces maintenance frequency and downtime. (LSI keyword use: 2)

Diamond Core Drills in Modern Projects

As materials become more advanced and project tolerances tighter, the demand for reliable diamond drilling solutions continues to grow. From smart infrastructure to precision electronics, diamond core drills play a critical role in enabling innovation.Manufacturers that invest in research, quality control, and application expertise help professionals stay competitive. This is why sourcing from trusted suppliers with proven experience—such as UKAM Industrial Superhard Tools—adds long-term value beyond the tool itself.

Frequently Asked Questions

What materials can diamond core drills cut?

Diamond core drills can cut concrete, reinforced concrete, granite, marble, ceramics, porcelain, glass, composites, and engineered stone.

Are diamond core drills better than carbide drills?

For hard and brittle materials, diamond core drills offer superior precision, longer life, and cleaner holes compared to carbide drills.

Can diamond core drills be used dry?

Yes, dry diamond core drills are available, but they must be designed specifically for dry use and paired with proper dust extraction.

How long do diamond core drill bits last?

Tool life depends on material, operating conditions, and bond quality. High-quality diamond core drill bits can last significantly longer when used correctly. (LSI keyword use: 3)

What RPM should I use with diamond core drills?

RPM varies by diameter and material. Always follow manufacturer recommendations to avoid overheating or premature wear.

Final Thoughts

Diamond core drills are more than just cutting tools—they are precision instruments that enable accuracy, efficiency, and reliability across industries. By understanding how they work, selecting the right configuration, and investing in quality manufacturing, professionals can achieve superior results while reducing overall costs.Whether you’re drilling through reinforced concrete or delicate ceramics, the right diamond core drills make all the difference in performance, safety, and long-term success.