Diamond core drills are essential tools for professionals who demand accuracy, efficiency, and reliability when drilling through hard and brittle materials. From construction and infrastructure projects to advanced manufacturing and laboratory applications, these tools provide clean, precise holes where conventional drills fail.As materials evolve and tolerances become tighter, diamond core drilling technology continues to play a critical role across multiple industries. Understanding how these tools work, their benefits, and how to select the right one ensures better performance, reduced downtime, and longer tool life.

What Are Diamond Core Drills?

Diamond core drills are cylindrical cutting tools embedded with industrial-grade diamond particles on their cutting edges. Unlike traditional twist drills, they remove material by grinding rather than cutting, allowing them to penetrate extremely hard surfaces with minimal cracking or chipping.These drills are specifically designed to create accurate, smooth holes in materials that are otherwise difficult or impossible to drill using standard tooling.

Materials Commonly Drilled Using Diamond Core Drills

Diamond core drilling is widely used because of its versatility across hard and fragile materials, including:

- Reinforced concrete and masonry

- Natural stone, granite, and marble

- Ceramics and porcelain tiles

- Glass and quartz

- Sapphire and advanced composites

- Engineered stone and sintered materials

This adaptability makes diamond core drills indispensable in both heavy-duty industrial environments and precision-based applications.

Key Advantages of Diamond Core Drilling Technology

Superior Precision and Accuracy

Diamond core drills produce consistent hole diameters with tight tolerances, making them ideal for applications requiring dimensional accuracy.

Minimal Material Damage

Because the drilling action is abrasive rather than impact-based, surrounding material remains intact, reducing cracks, fractures, and edge damage.

Extended Tool Life

High-quality diamond bonding systems significantly extend tool lifespan, even under demanding drilling conditions.

Cleaner and Faster Drilling

Diamond core drills generate less vibration and debris, resulting in smoother finishes and improved productivity.

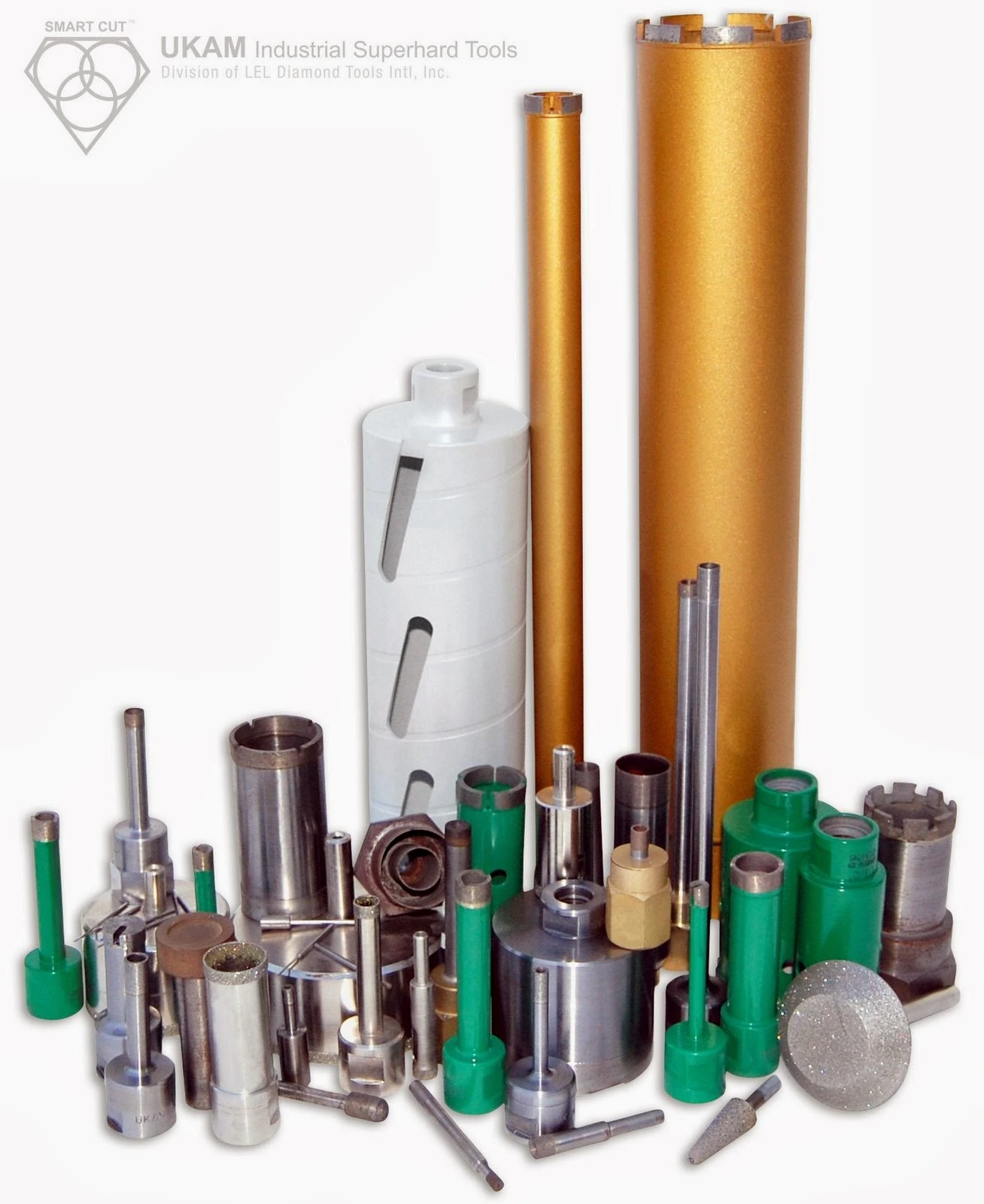

Types of Diamond Core Drills

Understanding the different types of diamond core drills helps in selecting the right solution for your application.

Wet Diamond Core Drills

These drills use water or coolant to reduce heat, control dust, and extend tool life. They are commonly used in construction, stone processing, and industrial manufacturing.

Dry Diamond Core Drills

Designed for applications where water is impractical, dry drills are ideal for on-site work and indoor installations, often featuring specialized segments for heat dissipation.

Electroplated Diamond Core Drills

Best suited for precision drilling in glass, ceramics, and laboratory environments, these drills offer sharp cutting action and excellent accuracy.

Sintered and Vacuum Brazed Core Drills

Used in high-production environments, these drills provide stronger diamond retention and longer service life.

Industrial Applications of Diamond Core Drills

Diamond core drills support a wide range of professional applications:

- Construction and civil engineering

- HVAC and plumbing installations

- Electrical conduit drilling

- Stone fabrication and countertop installation

- Aerospace and automotive manufacturing

- Medical device and laboratory equipment production

In precision-driven industries, consistent results and repeatable performance are essential—qualities that diamond core drills deliver reliably.

How to Choose the Right Diamond Core Drill

Selecting the right drill involves more than just size. Consider the following factors:

Material Type

Different materials require different diamond grit sizes and bonding systems to achieve optimal cutting efficiency.

Hole Diameter and Depth

Accurate sizing ensures proper fit and prevents unnecessary wear or tool failure.

Drilling Method

Determine whether wet or dry drilling is appropriate based on the work environment and material sensitivity.

Machine Compatibility

Ensure the drill is compatible with your drilling equipment, including RPM range and mounting type.

Quality and Manufacturing Standards

Tools manufactured under strict quality control deliver consistent performance and enhanced safety.Manufacturers like UKAM Industrial Superhard Tools are known for engineering diamond drilling solutions that meet the demanding requirements of modern industries.

Best Practices for Using Diamond Core Drills

To maximize performance and longevity:

- Maintain recommended drilling speeds

- Use proper cooling or lubrication when required

- Avoid excessive pressure during drilling

- Secure the workpiece to minimize vibration

- Inspect drills regularly for wear

Following these best practices improves drilling efficiency and reduces overall operational costs.

The Future of Diamond Core Drilling

Advancements in diamond bonding technology, material science, and manufacturing processes continue to enhance the performance of diamond core drills. Innovations now focus on longer tool life, faster cutting speeds, and improved sustainability through reduced waste and energy consumption.As industries adopt smarter and more precise machining methods, diamond core drilling remains a foundational technology supporting growth and innovation.

Frequently Asked Questions

What makes diamond core drills better than traditional drills?

Diamond core drills use abrasive diamond particles rather than cutting edges, allowing them to drill through extremely hard materials with greater precision and less damage.

Can diamond core drills be used on reinforced concrete?

Yes, diamond core drills are specifically designed to handle reinforced concrete, including steel rebar, when used correctly.

Do diamond core drills require water?

Not always. Wet drilling is common for heavy-duty applications, but dry diamond core drills are available for environments where water use is restricted.

How long do diamond core drills last?

Tool life depends on material hardness, drilling technique, and drill quality. High-quality drills can last significantly longer with proper use.

Are diamond core drills suitable for precision applications?

Absolutely. They are widely used in industries requiring tight tolerances, smooth finishes, and consistent hole quality.

Final Thoughts

Diamond core drills are more than just cutting tools—they are precision instruments engineered for performance, durability, and reliability. Whether used in construction, manufacturing, or advanced technical applications, their ability to handle hard materials with accuracy makes them indispensable in today’s industries.Choosing the right diamond core drill and using it correctly ensures efficient operations, reduced material damage, and superior results that meet modern professional standards.