Diamond core drills are essential tools for professionals who require accuracy, clean edges, and efficient material removal. Whether you’re working with glass, ceramics, composites, stones, or semiconductor substrates, the right drill can significantly improve results, reduce scrap, and extend tool life. With manufacturing and engineering demands becoming more advanced, choosing the correct diamond core drill is no longer optional—it’s a key factor in productivity and long-term cost savings.

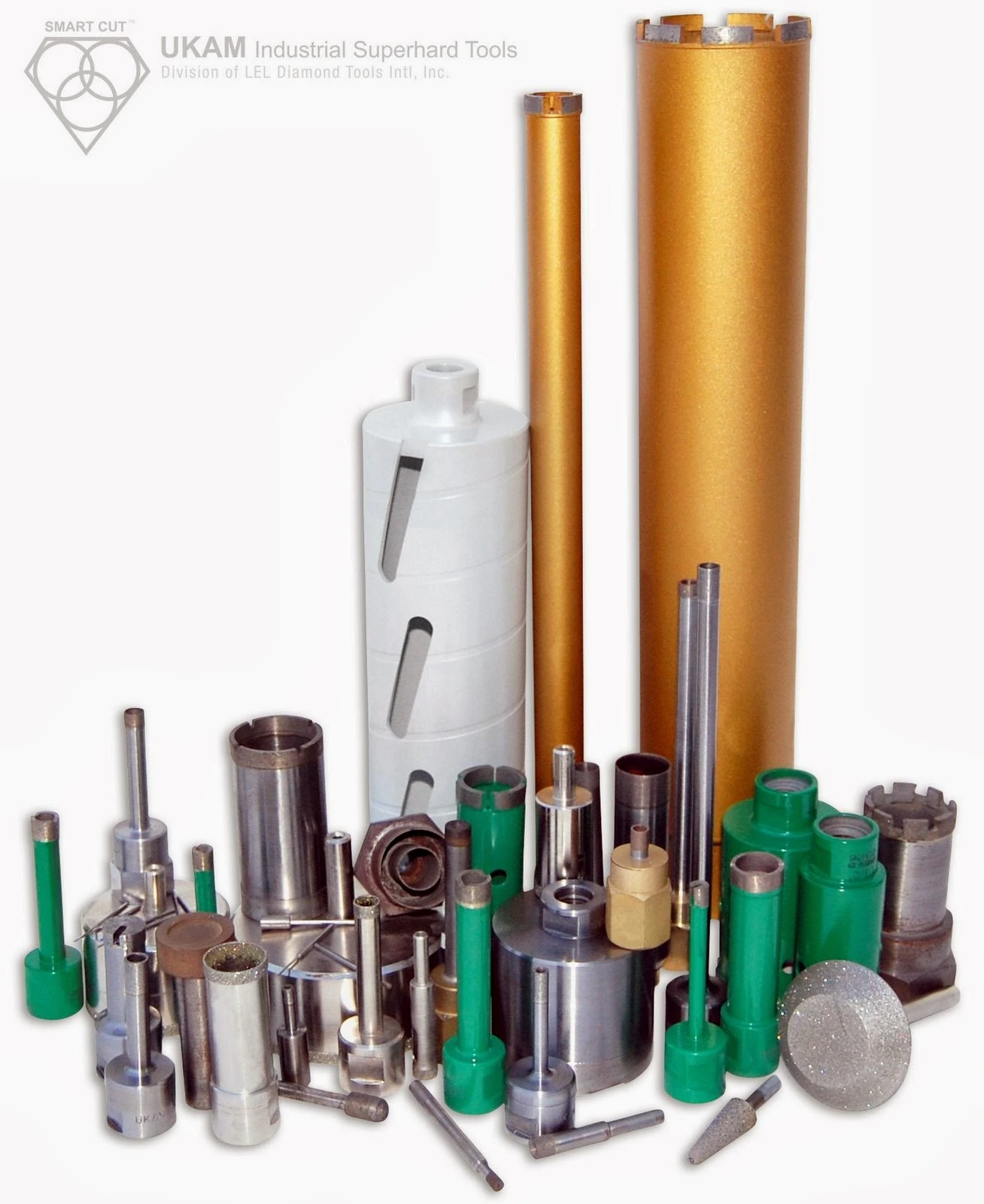

From understanding drill types to analysing material properties, drilling speeds, lubrication methods, and application-specific setups, this guide provides everything you need to make an informed decision. For reliability and consistent performance, many industries trust UKAM Industrial Superhard Tools for advanced diamond drilling solutions.

What Are Diamond Core Drills?

Diamond core drills are precision tools engineered with diamond-coated or diamond-impregnated rims that grind through dense and brittle materials. Unlike standard drills that cut through materials using sharp edges, these drills use the hardness of diamond to grind, which results in smoother, cleaner holes and minimized chipping.

Types of Diamond Core Drills

Different applications require different drill configurations. Here are the most common types used across manufacturing, fabrication, and R&D labs:

1. Sintered (Metal Bond) Diamond Core Drills

These drills are made by sintering diamond grit into a metal bond matrix. They offer long life, aggressive cutting action, and consistent performance across harder materials like quartz, technical ceramics, and stone. Ideal for: production environments where longevity matters.

2. Electroplated Diamond Core Drills

Electroplated drills have a single diamond layer bonded to the surface. They deliver sharp, fast cutting and work well on softer or more brittle materials. Ideal for: glass, composites, sapphire, and delicate surfaces.

3. Hybrid Bond Core Drills

A combination of metal and resin bonding. Hybrid drills provide smoother cutting, reduced heat, and high accuracy. Ideal for: semiconductor wafers, optical materials, and applications where precision is crucial.

4. Vacuum-Brazed Diamond Core Drills

Designed for rapid cutting and durability, vacuum-brazed drills maintain diamond exposure for tough applications. Ideal for: heavy-duty drilling in dense stone and hard industrial materials.

Selecting the Right Diamond Core Drill

Choosing the correct drill involves evaluating factors beyond standard specifications. Below are the elements that most influence performance and results.

1. Material Properties

Each material responds differently to drilling pressure, speed, and lubrication.

Glass: requires sharp, fast-cutting electroplated drills

Ceramics: benefit from sintered or hybrid bonds

Granite/Stone: perform best with vacuum-brazed or sintered drills

Wafers & Electronics: need ultra-precision hybrid or resin bond tools

2. Hole Diameter and Depth

Large-diameter holes generate more heat, requiring high lubrication levels. Deeper holes need proper chip evacuation to avoid material damage.

3. Drill Bond Type

The bond determines the cutting speed, heat resistance, and tool life. Always match the bond type with the hardness and abrasiveness of the material.

4. RPM and Feed Rate

Incorrect RPM is one of the main causes of tool wear and chipping. Softer materials often require higher speeds, while harder materials perform better at lower RPM with steady feed pressure.

5. Coolant or Lubrication

Water, synthetic coolants, or mist lubrication reduce friction, remove debris, and extend tool life. Proper cooling also prevents cracks in sensitive materials.

6. Mounting and Machine Type

Handheld drills, CNC machines, drill presses, and automated systems all have different requirements. Stability and alignment play a major role in final hole quality.

Benefits of Using High-Quality Diamond Core Drills

Superior Accuracy

Diamond’s hardness ensures minimal deviation and smoother hole geometry.

Reduced Chipping and Cracks

Properly matched drills create cleaner edges, especially in brittle materials.

Longer Tool Life

Sintered and hybrid bond drills maintain sharpness over extended use.

Faster Material Removal

Diamond drills grind rather than cut, enabling faster operation without compromising precision.

Versatility Across Industries

Used in electronics, aerospace, medical device manufacturing, R&D labs, optics, construction, and more.

Applications of Diamond Core Drills

Industries rely heavily on these drills for:

Glass and borosilicate drilling

Porcelain and ceramic hole-making

Stone and natural mineral drilling

Advanced composites and fiber-reinforced materials

Semiconductor wafer processing

Optical lens manufacturing

Laboratory and prototype fabrication

Engineering testing and research

From small hobby projects to high-volume production, diamond core drills offer the accuracy needed for breakthrough results.

Common Mistakes to Avoid

Even the best drills cannot perform correctly if used improperly. Here are mistakes professionals should avoid:

Using incorrect RPM, causing heat buildup or cracking

Applying excessive pressure, resulting in premature tool failure

Insufficient lubrication, leading to friction and loss of accuracy

Selecting the wrong bond type for the material

Ignoring drill wear patterns, which reduces performance

Skipping break-in procedures, shortening tool life

Proper setup ensures consistent, high-quality results.

Why Professionals Choose Us

For advanced applications in drilling, cutting, and material fabrication, UKAM Industrial Superhard Tools is trusted worldwide. Their precision-engineered diamond core drills offer optimized performance, durability, and versatility across hundreds of materials. With decades of experience in superhard tooling, they provide technical guidance, customization, and high-performance solutions for demanding industries.

Best Practices for Longer Tool Life

To maximise tool efficiency and lifespan:

Use adequate coolant flow

Maintain correct RPM for material hardness

Start with a steady, controlled feed

Allow the drill to self-sharpen during operation

Use proper fixturing to maintain stability

Clean drills after use to avoid residue buildup

Consistent maintenance can significantly extend drilling performance.

Frequently Asked Questions

1. What materials can diamond core drills cut?

They can drill through glass, ceramics, stone, composites, minerals, carbon fiber, and semiconductor materials with high precision.

2. Do I need coolant for drilling?

Yes. Coolant reduces heat, prevents cracks, and greatly improves tool life.

3. How long do diamond core drills last?

Lifespan depends on bond type, material hardness, RPM, and lubrication. Sintered drills last much longer than electroplated ones.

4. Can diamond core drills be used on a hand drill?

Yes, as long as the drill is stable and adequate lubrication is provided.

5. What is the difference between sintered and electroplated drills?

Sintered drills have multiple diamond layers for long life; electroplated drills cut faster but wear quicker.